Absorption Heat Transformer

Technology Overview

The AHT cycle operates as follows:

- The waste heat drives the cycle by enabling the desorption. separating the refrigerant from the absorbent solution, which is normally an aqueous LiBr solution. This occurs in the generator.

- The refrigerant vapour flows through the condenser, where the vapour latent heat is transferred to a dissipation sink at a low (ambient) temperature.

- After being condensed, the refrigerant is pumped to a higher pressure, where the refrigerant is evaporator by the waste heat source.

- Finally, the vapour goes from the evaporator to the absorber. The LiBr concentrated solution absorbs this vapour and due to this exothermic process, the absorption heat is released at higher temperature. Thus, the revalorized stream from the AHT may be delivered to the corresponding application.

Objectives:

Demonstrate the potential of mechanical vapour compressor and thermally driven heat pumps to upgrade waste heat in the large scale (> 500 kW) in relevant industrial sectors with high waste heat recovery and upgrading potential, with supply temperature in the range 90-160°C.

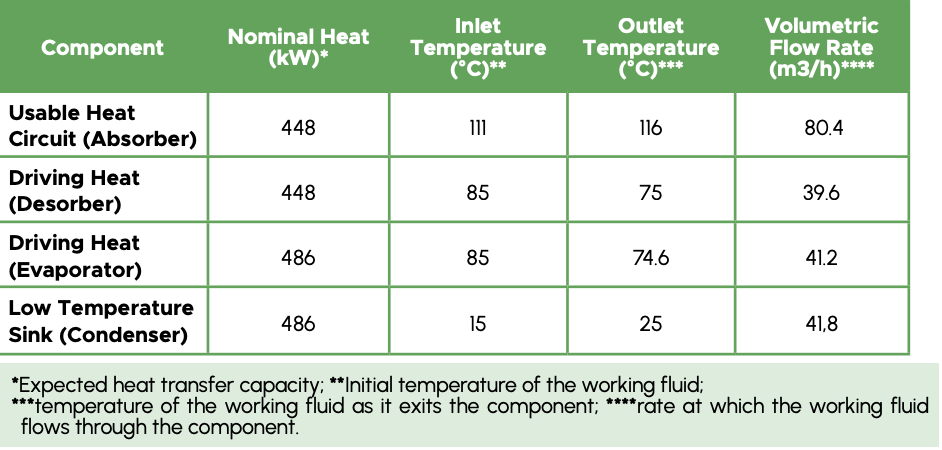

Operating Conditions