Vapour compression heat pump with turbo-compressors

Technology Provider

To be integrated at Guarcino Demo Site

About the technology

Enertime’s High Temperature (HTHP) and Steam Generating (SGHP) Heat Pumps produce useful heat in industrial processes and district heating networks by valuing industrial waste heat or renewable resources. These heat pumps are adapted to industrial heat applications requiring high temperatures and over 3 MW of heat.

With an optimized modular design to meet each project requirements, the Heat Pumps are adapted to the specific needs and constraints of the host process, while maximizing their performances (COP). Enertime centrifugal compressors are optimized for the Heat Pumps and project specificities, with the capability of producing steam, pressurized water and hot air production above 100°C.

These systems allow the combined integration with steam compression and heat recovery systems, also adaptable to specific heat sources (corrosives, fouling, etc). And finally, each heat pump system is designed project-specific based on the location and accessibility constraints. Robustly thought-out, Enertime’s Heat Pumps minimize as much as possible operating and maintenance constraints. Fully automated, Enertime’s products allow fast start-ups and stops and a remote supervision, with high availability.

The Heat Pumps use new-generation non-flammable HFO fluids with very low global warming potential, or Alkane fluids, custom-made centrifugal compressors with high rotation speeds and compression ratios up to 3.2. Enertime compressors either use a geared driver with up to 3 compression stages, or 1-2 compression stages directly driven by a high-speed motor with magnetic bearings in a hermetic enclosure to reach the highest possible performance while ensuring an oil-free and wear-free operation, low vibration rates, and low noise emissions.

Technical details

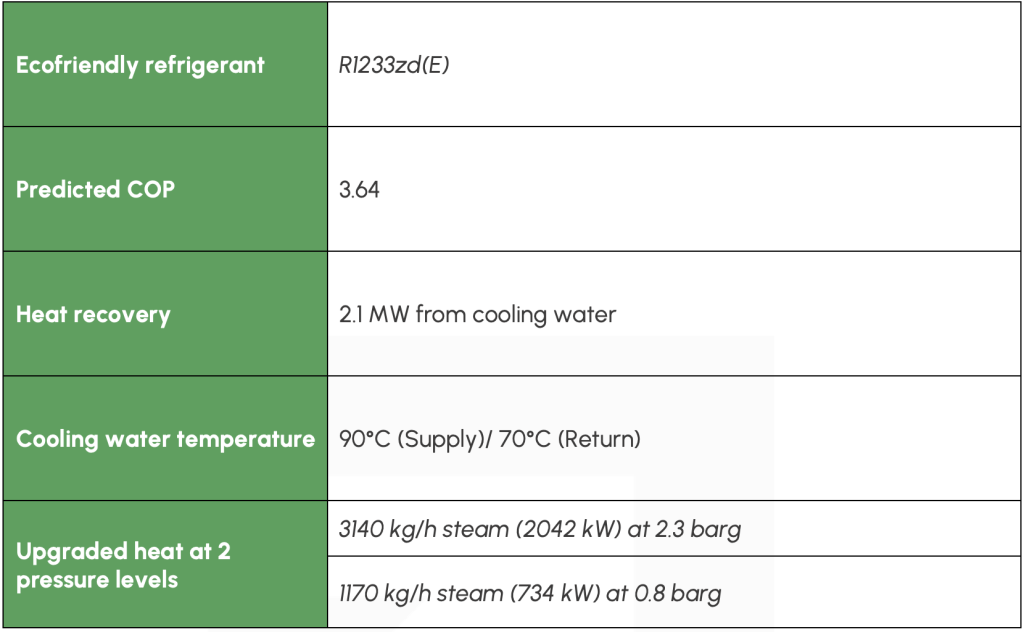

The heat upgrade technology utilized in demo site 2 will be manufactured by ENERTIME, using high-temperature heat pump, featuring a two-stage centrifugal compressor, employing the environmentally friendly refrigerant R1233zd(E). The predicted COP is approximately 3.64.

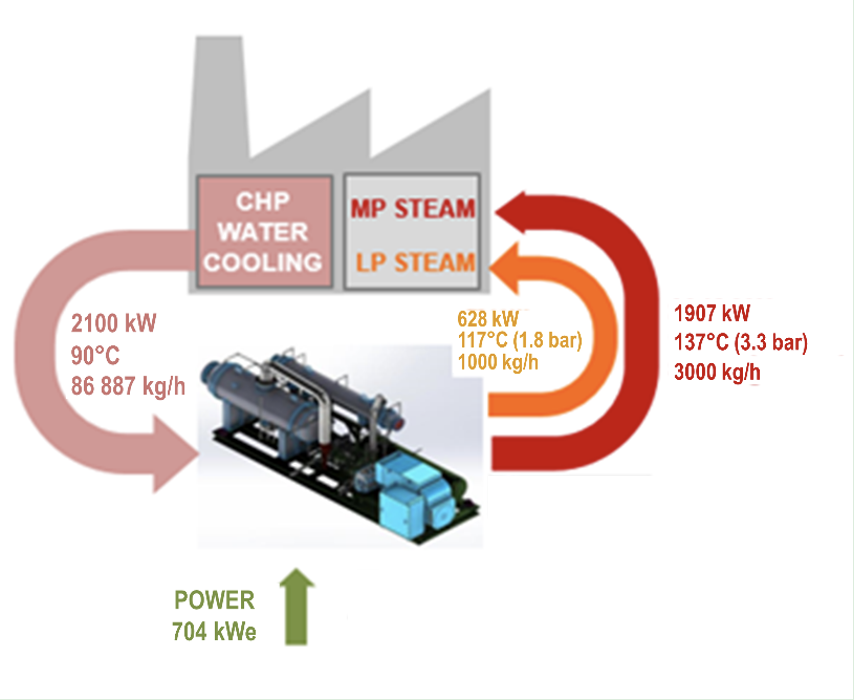

The Heat Pump valorizes the waste heat from the cooling water system of the cogeneration plant. This cooling water is conveyed to the heat upgrade system, where it will transfer the captured heat to the evaporator of the heat pump. The supply and return temperature of the cooling water are respectively around 90 °C and 70°C.

By cooling down this stream it is possible to recover around 2.1 MW of heat at the evaporator.

Upgraded heat will be available in the form of steam at two different pressure levels:

- 3140 kg/h of steam (2042 kW) at 2.3 barg.

- 1170 kg/h of steam (734 kW) at 0.8 barg.

The high-pressure steam is produced within the Heat Pump's condenser, whereas the low-pressure steam will be produced through the Heat Pump cooling process of the refrigerant in the intercooler.

After the Heat Pump system, a thermo-compressor is used to raise the pressure of high-pressure steam to up to 5.5 barg. Therefore, this allows the integration of the generated steam in the medium pressure collector to supply the steam for the paper machines. The low-pressure steam at 0.8 barg is foreseen to supply the deaerator of the plant.

Expected impact