High-Temperature Heat Pump

Technology and knowledge provider and system integrator

To be integrated at Guarcino Demo Site

Performance Assessment

About the technology

The technology to be scaled up in DEMO 2 is a High-Temperature Heat Pump (HTHP) capable of producing steam both directly and indirectly for industrial processes. It operates within a wide temperature range—from 60°C (sub-atmospheric) up to 160°C—making it suitable for recovering and reusing various sources of waste heat. These systems are modular and customizable, allowing tailored configurations for different industrial applications, with capacities ranging from 300 kW to 3 MW and based on different compressor technologies.

The HTHPs will use organic or natural refrigerants with zero/almost zero ozone depletion potential (ODP) and a global warming potential (GWP) below 5, ensuring high efficiency and minimal environmental impact.

Technical details

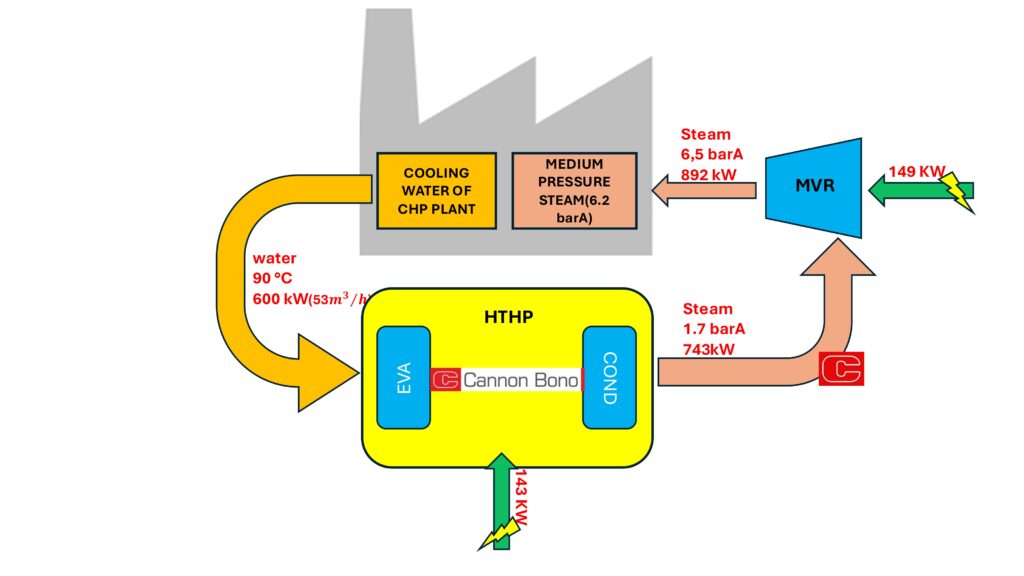

Two stage upgrades: Heat Pump + MVR

Eco-Friendly Refrigerant: R1233zd(E)

Heat recovery: 600kWth from Cogeneration cooling water which will be cooled from 90°C to 80°C

Overall COP of the system: 3

Delivered steam: 1310 kg/h at 6.5 barA

Challenges of integration

The main challenges for adopting industrial high-temperature heat pumps (HTHPs) are their high upfront costs and the need for a coefficient of performance (COP) high enough to compete with the electricity-to-gas price ratio. To address this, Cannon Bono is developing a direct steam-producing screw compressor heat pump using the low-GWP refrigerant R1233zdE, which ensures safety and efficient high-temperature steam production. An oil-free screw-type Mechanical Vapor Recompression (MVR) system is also being implemented to deliver pure steam while reducing operational and maintenance costs. The combination of the screw heat pump and MVR offers the most promising balance between performance and cost for common industrial applications.

Expected Impact

Within PUSH2HEAT, Demo2 aims to recover around 600kW heat from the cooling water of a cogeneration plant to produce 1310 kg/h of steam. With the evaporation temperature of the heat pump at 70°C and delivered steam at 6.5 barA (162°C), the system has a COP =3.