Thermochemical Heat Transformer

Technology by Qpinch

About the technology

The Qpinch thermochemical heat transformer (QTHT) is a thermally driven heat upgrade technology that converts waste heat into carbon-neutral industrial heat. It is designed for MW-scale projects with temperature lifts of several tens of degrees, making it suitable for implementation across all thermal processing industries. The heat recovery technology is almost solely driven by waste heat at low to intermediate temperatures. A limited amount of electricity is used to circulate the working fluids.

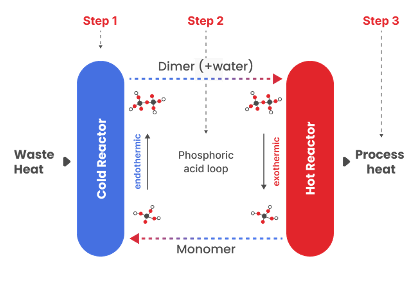

The temperature lifts in the QTHT are realised by using a physicochemical process with phosphoric acid. The core reaction comprises the endothermic dimerization of phosphoric acid and the reverse, exothermic hydrolyzation of the dimer, setting free heat at high-temperature. By exploiting the reversible chemical reaction low-grade waste heat can be transformed into process heat.

Technology diagram

Step 1: Capturing waste heat. Currently large amounts of residual energy is released in the atmosphere, directly or via cooling. Qpinch can absorb waste heat of 80°C and higher.

Step 2: Transforming waste heat. A physicochemical reaction transforms the captured low temperature waste heat to high temperature process heat. No electricity is needed to drive the temperature lift.

Step 3: Delivering new energy. 50% of the residual heat is recovered and transformed into process heat with temperatures up to 210°C on MW scale.

Expected Impact